QComp Industries

Solving Complex Material Handling Challenges

Serving Global Brands

Overcoming complex material handling challenges is where QComp shines. Explore our industry applications below and connect with our experienced team to talk about our proven solutions.

Are you in an industry not listed below and need a robotics integration solution? We can help.

It went smoothly, and just as expected. It’s just easy to work with the QComp team.

Doug L.

Satisfied glass partner

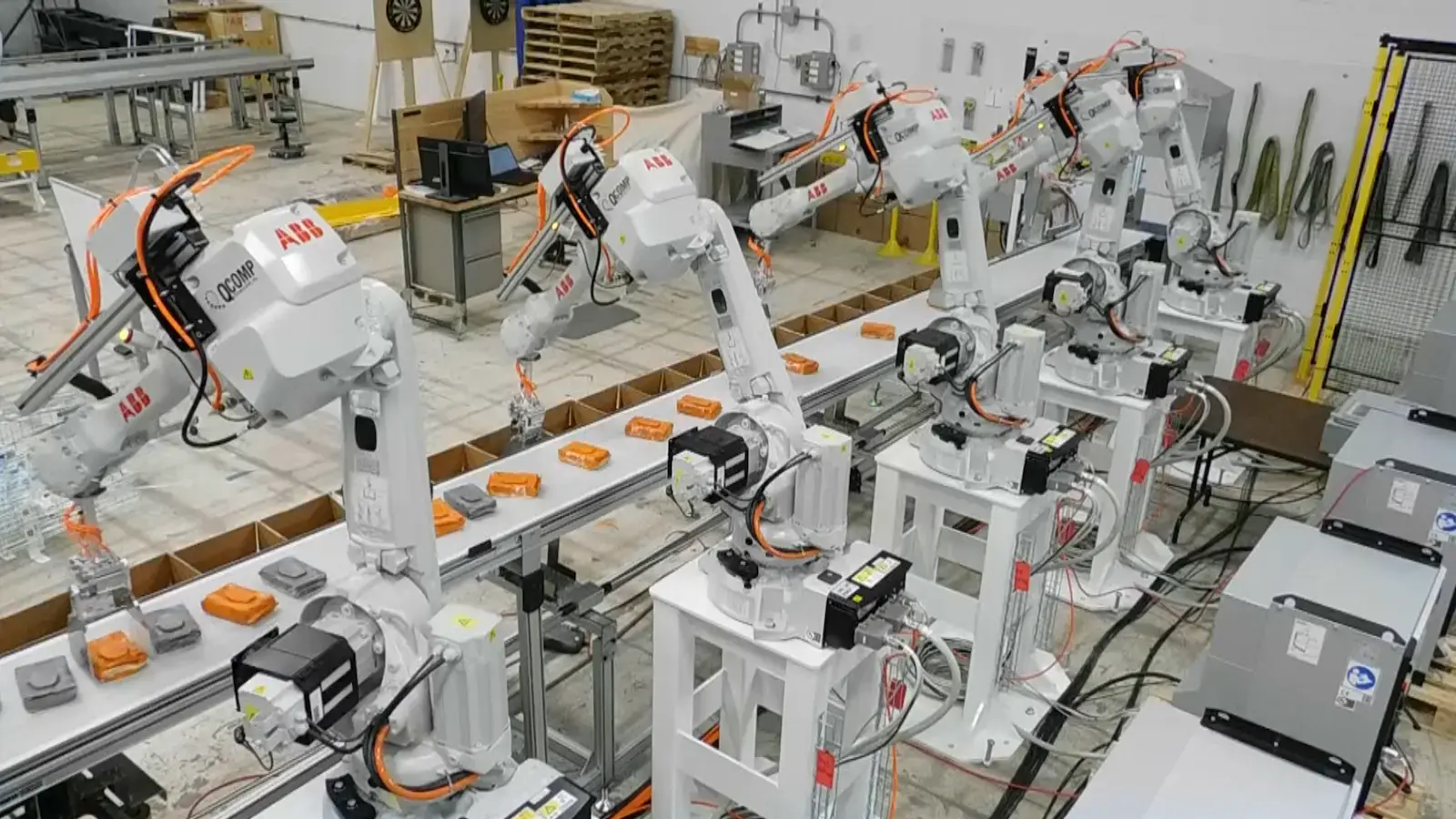

Glass

QComp’s robotics handling systems shatter the competition, not your products! Vision-guided robotic solutions manage large pieces of fragile glass with speed, precision, and reliability, significantly reducing scrap and the risk of workplace injuries.

In particular, QComp’s ingenuity is recognized among glass industry leaders for developing systems that can:

- Load and unload glass lines

- Pack to an L-rack, slotted rack, or box

- Convey glass to production lines

- Assemble windows and doors

- Package assembled products

- And more

Consumer Goods

Improving operational efficiencies is the battle cry of many producers of consumer goods. QComp’s robotics solutions help improve production, changeover times, and speed to market, and are adaptable to multiple SKUs.

Both standard and complex robotics functions can be achieved, allowing manufacturers to pick, place, transfer, assemble, package, and palletize popular consumer goods, even those that must remain in compliance with strict regulations. Additional applications include:

- Personal care products and cosmetics

- Cleaning supplies and toiletries

- Electronics

- Home goods

- And much more

Non-Woven Products

The challenge of non-woven material packaging processes has plagued manufacturers for years. QComp has mastered these capabilities and has also perfected precise packaging and lidding for products like:

- Disposable wipes

- Dryer sheets

- Paper products

- And more

Food & Beverage

Many food products are inconsistent from one to the next, making it difficult for a robotic arm to adapt quickly and accurately when picking or placing items. QComp has mastered the programming of robots to adapt to inconsistencies and improve throughput.

QComp understands the importance of complying with rigorous food safety standards for a wide range of food handling applications, including high-pressure, high-temperature, hygienic, and caustic washdown robotic solutions:

- Loading thermoforming trays with meat products

- Packing cases of fruit, vegetables, and canned goods

- Palletizing beverages for transport

- And more

Contact Us

We’re up for the challenge! Complete the form below and we’ll be in touch soon.

Latest QComp News

Why A3 Safety Certification Matters for Robotic Integrations

What is A3 safety certification? Explore the benefits and importance of The Association for Advancing Automation (A3) certification for robotic integrators.

What is Proactive Development of Robotic Solutions?

What is the proactive development of robotic solutions for complex material handling challenges in manufacturing, and what are its benefits? Learn more.

Jumbo Glass Robotics

Learn how QComp is pushing the limits on the ability to pick and inspect an extremely wide range of glass and glass assembly sizes & shapes.